To Grease Or Not To Grease?

In response to issues raised during Schaeffler Automotive Aftermarket Australia’s training events, the company advises repairers of some very important points in relation to the greasing of clutch release systems.

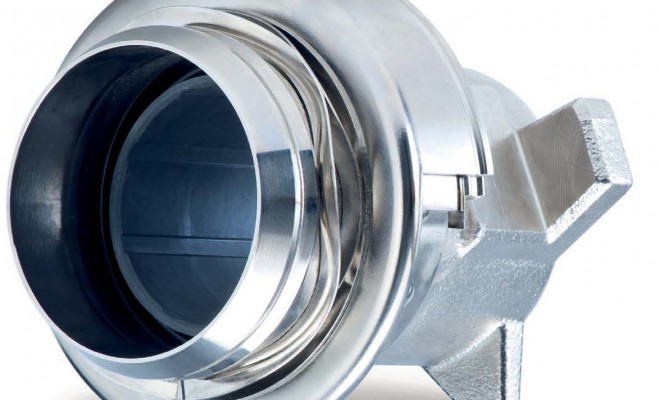

As most automotive technicians are well aware, a well-functioning clutch system features extremely smooth actuation. Therefore, it is imperative to have the smallest possible amount of friction between the release bearing and the guide sleeve.

The sliding sleeves of the release bearings can be manufactured from either metal or plastic. It is imperative when replacing clutch systems that the following greasing guidelines are adhered to.

- If the sliding contact surfaces of the release bearing and the guide sleeve are manufactured from metal they must definitely be greased.

- If release bearings with a plastic sliding sleeve are installed, these have already been coated with a thin lubricating film during the manufacturing process and therefore must not be greased.

Problems arise when mistakes are made with the lubrication or non-lubrication of clutch release systems based on their specific type, which can all too often lead to costly come backs for repairers and in turn, dissatisfied customers.

To find out more contact Schaeffler Automotive Aftermarket Australia Product Manager Brett Sage – 02 8977 1043.

(Picture shows plastic sleeved clutch release system that should not be greased.)